Industrial fires : modern strategies for prevention and response

09/11/2025

In today’s interconnected world, industrial fires represent one of the most significant threats to critical infrastructures and plant safety, with the potential to disrupt entire economies and major facilities in a matter of hours. From sprawling chemical plants, petrochemical centers, and oil refineries, to high-tech manufacturing hubs, the sheer volume of flammable material, combustible dust, hazardous substances, and complex equipment means that even a single ignition spark can trigger devastating incidents. Industrial safety practices and protection measures are critical to reduce the likelihood of workplace injuries, loss, and environmental damage due to fire. What are the modern strategies that industries deploy to prevent, detect, and respond to these high-stakes incidents? And how are new technologies reshaping the future of industrial fire safety and emergency response? Let’s dive into this vital issue, critical for every professional working to ensure compliant, certified operations and protect life.

Understanding industrial fire risks in critical infrastructures

What makes industrial fires particularly dangerous?

Industrial fire hazards are distinct from other types of incidents due to several aggravating factors in various settings:

- High volume of flammable materials: Factories, refineries, and storage facilities often house large quantities of chemicals, fuels, and flammable products. In these workplace environments, proper handling and employee training programs are crucial.

- Pressurized installations: Petrochemical processing units and oil facilities involve gases or liquids under pressure, raising the potential for explosion and challenging suppression and protection strategies.

- Complex building structures: Industrial buildings, warehouses, and processing centers often have interconnected spaces, which can hinder evacuation and require specific emergency response measures and evacuation protocols.

- Technological and electrical risks: Facilities depend on high-load electrical equipment, increasing the risk of ignition, arc flash, or explosion as a result of faulty maintenance, overloaded circuits, or outdated processes.

Specific causes in industrial environments

The most common triggers for industrial fires and explosions include:

- Gas leaks: Faulty pipes in oil facilities or processing plants can provide the potential for rapid flame spread or major accident.

- Short circuits: Often due to inadequate electrical system inspections or maintenance, a common challenge for plant administration.

- Human errors: Mishandling hazardous material, neglect of safety protocol, or poor training can cause incidents.

- Machine malfunctions: Overheated machinery/equipment, improper lubrication, or insufficient preventive maintenance can ignite fires.

Human, economic and environmental consequences

Industrial fires in critical infrastructures have a devastating impact on employees, businesses, and the environment:

- Life and injuries: Such incidents endanger workers, rescue teams, and the public, sometimes with multiple injuries or fatalities.

- Economic loss: Facility shutdowns, supply chain disruption, and direct financial loss to businesses; the challenge is stark. About 70% of companies experiencing a major fire never resume business.

- Environmental damage: Toxic smoke, hazardous substance spills, and water contamination impact entire ecosystems and provide long-term harm to air, soil, and water.

- Reputation: Affected companies suffer lasting damage to brand image, trust, and business continuity, emphasizing the necessity for compliance, best practice, and robust industrial fire protection.

Case study : lubrizol plant fire (france)

On September 26, 2019, a major fire broke out at the Lubrizol chemical plant (an upper-tier Seveso site) causing wide-reaching environmental, health, and economic impact. Approximately 9,500 tons of hazardous chemicals and oil products were destroyed, affecting multiple facilities. The thick smoke and release of harmful substances led to school closures, workplace disruptions, and regional intervention at several levels:

- Financial damage: Over €55 million in exceptional charges, including compensation to local farmers whose activities, such as food production, were suspended for safety. The incident set a precedent for robust indemnification programs and business recovery plans.

- Regulatory impact: Regulatory bodies reacted by strengthening standards, guidelines, and industrial safety protocols, requiring industries to proactively implement prevention and emergency measures.

- Reputation and trust: The Lubrizol case revealed challenges in crisis management, highlighting the necessity for improved risk communication, emergency protocols, and certified safety standards (NFPA, OSHA compliance).

Prevention, detection and suppression technologies

Risk mapping and predictive maintenance tools

Today, risk mapping, predictive maintenance, and advanced monitoring tools play a central role in industrial fire protection: • AI-powered analytics and smart sensors identify and address anomalies before they escalate, providing proactive hazard mitigation. • Automated inspections using drones and robotic technology help identify facility vulnerabilities in hard-to-access areas, increasingly common with the inclusion of digitalization in plant practice.

Detection systems: heat, smoke, gas

Interconnected fire alarm systems that include heat, smoke, and gas detectors are essential in any industrial setting. Early detection can mean the difference between disaster and recovery; these systems provide real-time alerts, reducing response time, and supporting the professional work of in-house and external emergency teams.

Fixed suppression systems in industrial contexts

• Sprinkler systems: A foundational solution for many warehouses and buildings, aimed at containing general fire outbreaks swiftly. • Foam systems: Used in oil, petroleum, and chemical industries where water may not be effective, foam smothers, impeding re-ignition. • Inert gas suppression: Essential in electrical departments, server rooms, or high-tech production environments where water would cause further damage. • Regular monitoring and upgrading of suppression equipment and addressing system blind spots are mandatory to ensure all unique risk areas are protected.

Robotic firefighting: transforming industrial fire response

How robotics improve safety and efficiency in high-risk environments

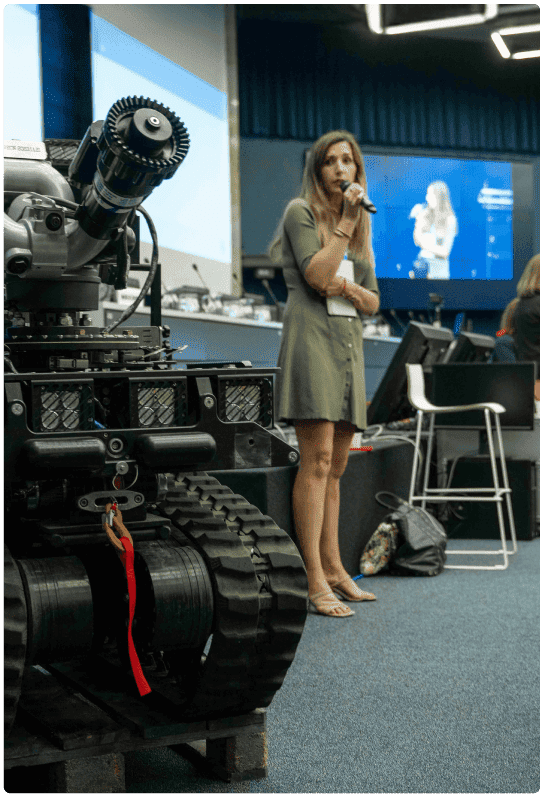

Robotic firefighting equipment is a game-changer for rescue operations in hazardous and high-risk sites, supporting both external responders and in-house emergency protocols. Trained professionals can now deploy certified robots in dangerous environments where human access is life-threatening, significantly mitigating employee risk and reducing potential loss.

Presentation of the Rhyno Protect by shark robotics

Among the forefront of these innovations is the Rhyno Protect by Shark Robotics, a compact and mission-focused firefighting robot designed to extend industrial fire response capabilities. Often referred to as the "little brother" of the larger Colossus model, the Rhyno Protect stands out for its lighter weight and smaller size, making it exceptionally agile and easy to deploy quickly.

This compactness enables industrial teams to initiate firefighting operations immediately upon alert, even before firefighters arrive on site, crucially limiting fire spread and damage at the earliest stages. Its user-friendly design features remote teleoperation via a tablet-based control system that provides real-time video and data feedback, facilitating precise maneuvering and effective fire suppression with minimal training.

The robot’s proven robustness has been demonstrated by its adoption by international fire brigades, including those in India, validating its performance across a variety of challenging industrial contexts. Built to withstand extreme temperatures and navigate difficult industrial terrains, the Rhyno Protect enhances firefighter safety by tackling the most dangerous tasks remotely and supporting early fire suppression efforts. By integrating the Rhyno Protect and similar robotic systems, industries can dramatically improve their emergency response outcomes, protect personnel, reduce property damage, and enhance overall operational resilience against industrial fire risks.

Building an efficient emergency response plan for industrial fires

Site-specific evacuation and confinement protocols

Every plan must account for unique facility challenges: • Define ATEX zones, create logical circulation and evacuation plans, and ensure refuge areas are equipped and accessible. • Regular implementation and review of these protocols reduce confusion and the likelihood of injury during major incidents.

Coordination between emergency services and in-house safety teams

A robust emergency response relies on seamless coordination between external emergency services and internal safety teams. Establishing a clear decision chain with defined roles and responsibilities is critical. Implementing real-time communication channels ensures rapid information sharing, enabling prompt decision-making and efficient deployment of resources during industrial fire events.

Integrating advanced tools (robots, drones, sensors) into drills

To maximize the effectiveness of emergency plans, industries must incorporate advanced technologies such as firefighting robots, aerial drones, and environmental sensors into regular training exercises. Conducting specific trainings and realistic simulations familiarizes teams with these tools, while systematic feedback and lessons learned help refine protocols, ensuring preparedness for complex and evolving fire scenarios.

FAQ

What is the average cost of an industrial fire?

Industrial fires contribute significantly to fire-related losses. n the U.S., with direct property damage to industrial and manufacturing properties averaging nearly $1 billion annually and total fire costs across all sectors exceeding $300 billion per year (including fire prevention, response, and indirect costs). Specifically, from 2017 to 2021, industrial/manufacturing property fires caused about $988 million in direct property damage each year in the U.S., according to NFPA. The overall fire losses nationally represent roughly 2% of U.S. GDP, reflecting the large economic burden of fire incidents.

What standards are in force?

Key standards include OSHA regulations for fire safety, NFPA 660 for industrial firefighting, API standards for oil/chemical plant safety, and the European Seveso III Directive for hazardous substance control. Compliance is essential for workplace safety and administrative protection. The European Seveso III Directive (2012/18/EU), which imposes strict requirements for controlling major accident hazards involving dangerous substances;

Contact our communications team